3D-Scan / Reverse Engineering

With our extensive expertise in 3D scanning and reverse engineering, we are able to digitize physical components with the highest accuracy. These digital models are the basis for the optimization, reproduction or further development of components.

Every project is individual, we provide you with comprehensive advice and develop the optimum solution together with you.

Our goal: a tailor-made, specific result that meets your expectations.

Our services at a glance:

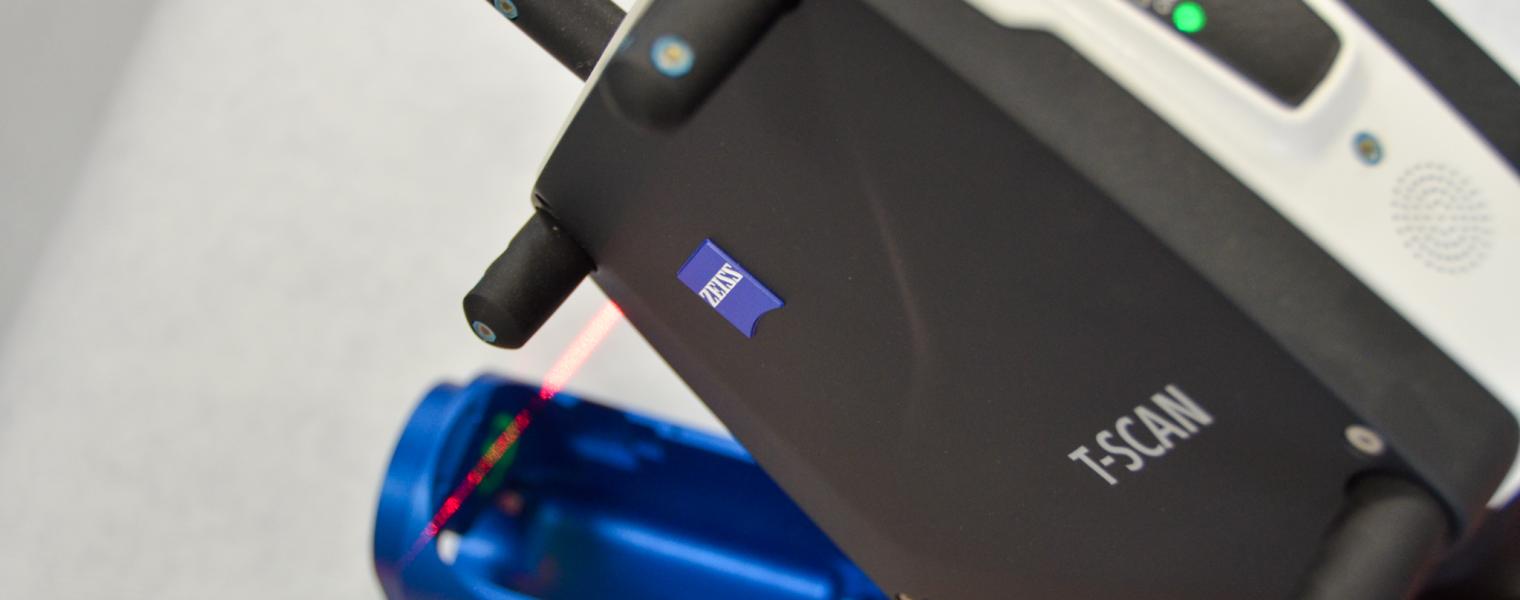

- 3D scan: we use the ZEISS T-Track to create digital models of existing components. These scans are the basis for analyses, design optimization and reworking.

- Data preparation: we create CAD models and production-ready drawings

- Reverse engineering: complex components are constructed on the basis of the 3D scan

Why PAYR?

We offer customized solutions that are tailored to customer-specific requirements.

Are you looking for a reliable partner? Contact us today and let us realize your ideas together.

Contact us now

Herzlichen Dank für Ihre Anfrage

Wir werden Ihre Anfrage so schnell wie möglich beantworten!